Savonia's 3D-scanning services

List of prices

- 3D-scanning: 130 € / hour + vat

- Includes work related to 3D-skanning (ie. preparing part for 3D-scanning, positioning, 3D-scanning)

- Travel expences

- Kilometre allowance by Finnish tax administration (2025: 0,59 € / km)

- Hourly rate 60 €/hour + vat

- Post-processing: 90 €/hour + vat

- Includes repairing of the surface model / remodeling as needed and delivery on the previously agreed file format.

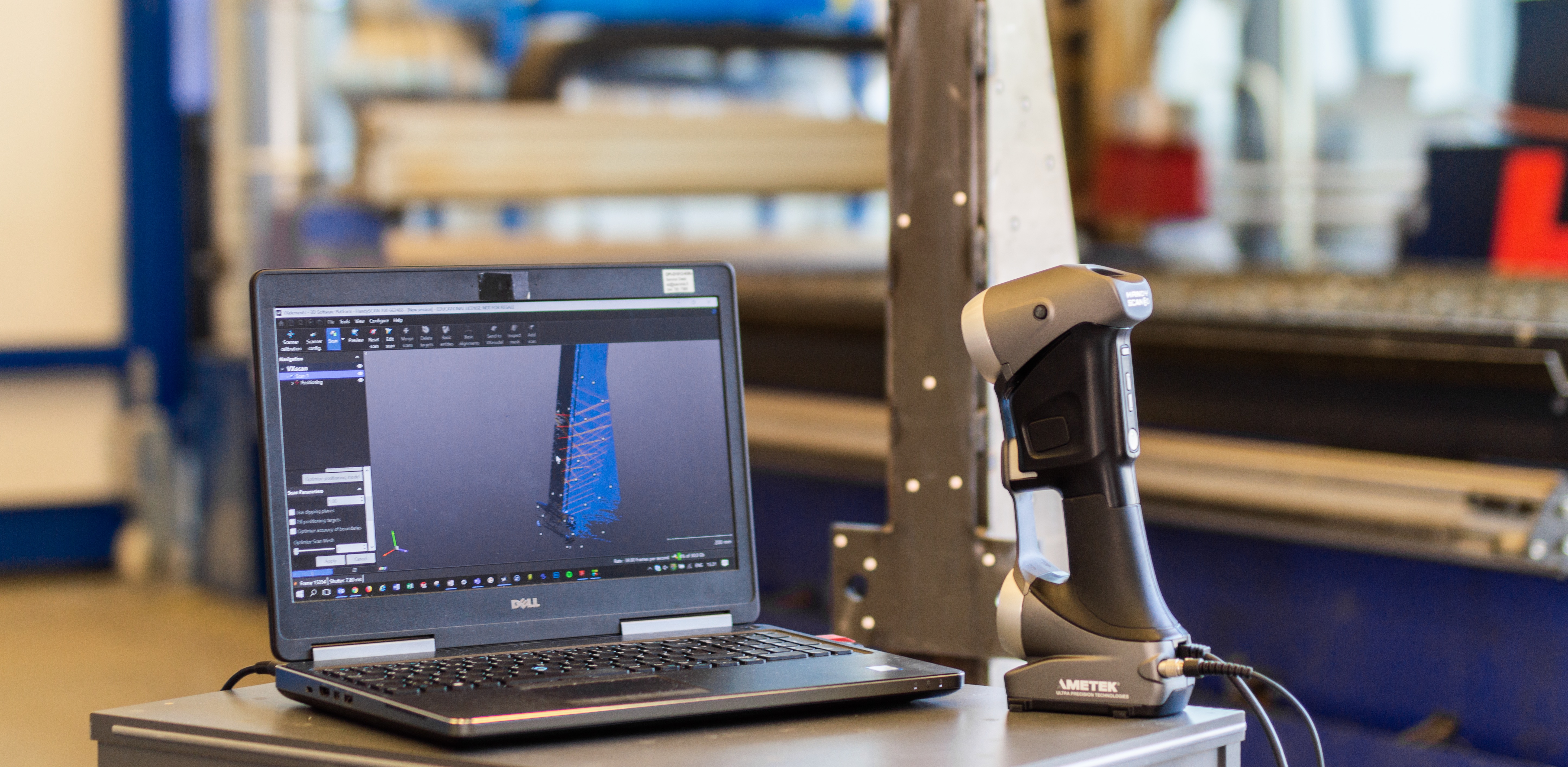

Softwares in use: Ansys Spaceclaim DirectModeler, Polyworks Inspector & VX Elements

Description:

The goal for 3D-scanning is usually a pointcloud or surface model for measuring or remodeling a real world physical object. Savonia's 3D-scanning equipment is suitable from heavy engineering workshop quality assurance to hobbyist projects.

It's imperative to take into account the goal and what 3D-scanning work entails as a whole. Just getting the surface model consists of multiple phases and if the model should be used for measuring or remodeling there is going to be a more phases to go trough. If the primary planning is wrong, the model might not be good enough for the next phase or the end use. The workphases are broadly:

- Pre-planning of 3D-scanning work: A detailed determination has to be done before starting the project (what needs to be scanned and at which accuracy, also what does not need to be scanned). Pre-planning reduces the wasted labour and the cost.

- Before scanning: The real world object needs to have positioning targets (stickers or magnets) to combine the consecutive scans to each other and the world. To get the best results from optical 3D-scanning the surface of the object has to be clean, nonreflective, nontransparent/-translucent and preferably white matte surface.

- 3D-scanning of the real world object.

- Postprocessing: The surface model is rarely perfect after 3D-scanning, so in most cases the model has to be fixed programmatically. This might include for example filling up occluded holes and cleaning of false measurements from reflections or other unnessessary details in the 3D-world. Sometimes the scanner software isn't enough for fixing the model, or the work would be too timeconsuming so the model has to be tranferred to separate surface modeling software, e.g. Ansys SpaceClaim.

- Further proseccing of the model: For example adding of features, reducing surface points without losing details or converting the surface model to solid model. For example Solidworks modeling program does not work really well with surface models, so there might be a need to convert the model from surfaces to solids using some reverse engineering tools, which are found e.g. in SpaceClaim.

- 3D-measuring: The scanned pointcloud/surfacemodel can be compared to an existing CAD-model, or incase of an unknown object measurements can be extracted from the features of the object. For this too there are dedicated programs, like InnovMetric Polyworks Inspector. (If the data from previous phases is corrupted or missing, extracting measurements might be really timeconsuming or impossible to obtain.)

The extent of 3D-scanning work and the time comsumption is almost directly propotional to part size (for optimal scanning surface). From a smallish 1 litre milk bottle an unbroken surface model can be extracted in less than an hour. Measuring the previous example part takes approximately half an hour. Of course the complexity of the model can exponentially increase the use of time. Also when going smaller, features become harder to extract due to reflections and occlusions so the assesment of worktime for any given part isn't always easy.

The biggest sensible 3d-scannable part for Savonia's handheld 3D-scanner (Creaform HandySCAN 700) is about the size of small passenger car. For 3D-scanning said object time consumption will be in range of 1 to 2 days. Possible measurements can easily take another day more, depeding how many features/measurements should be extracted (approximately 1 day / 50 measurements).

Modifying/repairing surface models is an another project altogether. Almost the only common thing in these projects is usually fixing the model to an watertight mesh. Small uncomplex parts are quite straightforward and wont take more than couple of hours, but for bigger or more complex parts just fixing holes/features might take days. When refering to 3D-model size it's not just the size of the model but also the surface complexity that counts. For example a cube is a simple object no matter if it is the size of the universe or 6 sided dice. However if we increase the surface complexity enough, not even an supercomputer can handle the model of 6 sided dice in any sensible amount of time.

If you saw something of interest and have a potential project, ask more from our specialists!