The effects of 3D-printing to business activities

The dialogue in the publications concerning Additive manufacturing/3D-printing is mostly about technological development of the printing technologies, -methods and -materials.

The business of the 3D-printing devices and –materials has been developing and growing at a fast pace. Big technology companies around the world are investing on new manufacturing technologies and new products, to improve customer operation quality and cost-efficiency.

The big question is that, will the traditional sector of small and medium enterprises in Finland follow suit and begin to utilize AM-technologies and develop their operations proactively? Or will the companies only take action as the competition dictates?

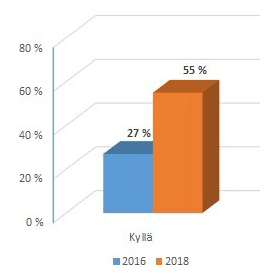

A survey of Savonia University of Applied Sciences, tried to find answers for developing AM in the area of Northern Savonia. The Hype has not yet reached the companies of northern Savonia – A big change is yet to come. The Survey was done on 2016 and 2018. One of the questions was about whether the companies see any effects or potential of 3D-printing for the operations of their company. The survey was done by using email and phone. The target group was about 300 Northern Savonia’s companies and at both times, about 50 replies were received.

Picture 1: Answers of Northern Savonia’s companies to whether they use or plan to use 3D-printing now or in the future. There was a clear change between the survey’s.

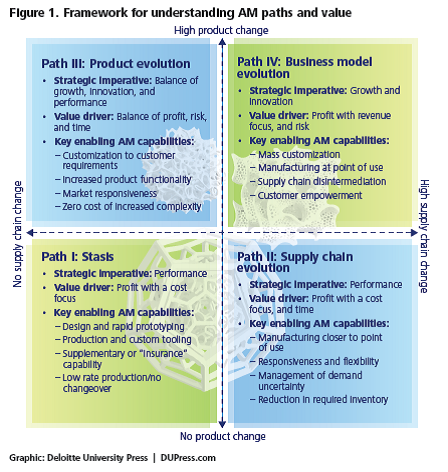

With the additive manufacturing new business-models have also surfaced. For many, especially small companies the investments for current products and production change relatively slowly. Why do the same thing differently if not for cheaper? Could rethinking of the business model bring new perspectives for adapting and benefiting from AM-technologies?

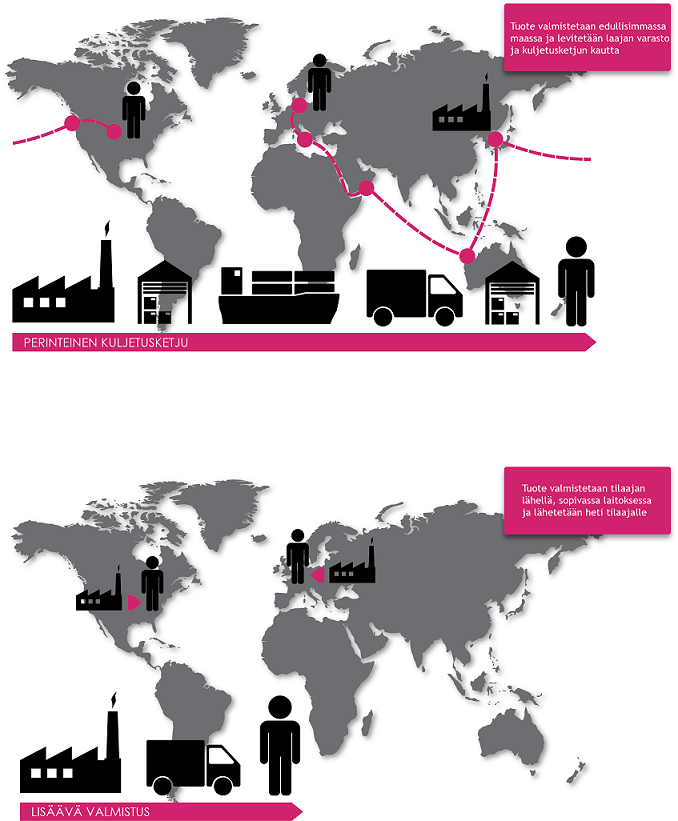

Technology companies have started to find new business possibilities from services like after-sales service and spare-parts. This offers new possibilities for developing cost-effective production using 3D-printing. According to studies, the logistics will become more straightforward and cost-efficient for example by adapting on-demand methods for spare part shipments. In addition to smaller raw-material cost and material loss, there will be savings from lighter logistics network and from customer service improvements.

In addition to product changes, the commissioning of Additive manufacturing can also be seen as a whole supply-chain change towards new business models. Big product changes together with big changes on supply-chain produce new business models and offer new possibilities for developing the business. Change paths as an example for product- and supply-chain changes:

- status quo - cost focus

- development of supply-chain – profit, cost and time in balance

- evolution of product portfolio – profit, risk and time in balance

- development of business model – profit as a focus of revenue, risk

Picture 2. Change paths to new business model, Source: Deloitte University Press, 17.1.2014

Picture 3. Example of the change on supply-chain