Materials

Plastics in general

These pages contain general information of plastics used in AM processes. The information isn't meant to be exhaustive or even list the most common materials, for that we provide some links to plastic manufacturers/resellers web-pages. It's good to keep in mind that while materials from different manufacturers migh be sold with the same name/abbrevation the materials can have different properties depending on the used components among other things. While this is true for all materials, with plastics the material manufacturers and resellers usually don't list the used components, and only some of the properties of the actual material.

Below listed some plastic material manufacturers/resellers, which have material specific properties listed on their websites.

| Link | Plastic material |

| Formfutura | filament, UV-resin |

| Maker3D | filament, UV-resin, powder |

| 3DJake | filament, UV-resin |

Metals in general

These pages contain general information about metals and metal-alloys used on additive manufacturing processes. The properties of the metals can differ between different manufacturers. The material information here is just in general, for exact information always refer to material manufactrurer.

Depending on the AM-method, the material can be in different forms, ie. powder, wire, sheet, paste, etc.

Powdermaterials differ from each other by eg. metal alloy components, particle size and particle shape. Particle size and shape are mainly affected by the used atomization process. After the atomization process the powder is usually sieved to separate/remove too big and small particles. A round shaped particles have better flowability than angular shaped particles.

There are at least 3 different atomization processes ie. gas-, water-, and plasma atomization. Atomization prosess breaks down the material to powder particles. The processes differ a lot from each other, eg. Wateratomization process breaks down the material using high pressure water spray from a nozzle, which creates uneven shaped particles. Water atomization process works mainly for nonreactive metals. In gas- and plasma-atomization processes the material is melt and sprayed to an inert collection chamber. Collection chamber can use either protective gas or vacuum for the inert environment. The spray cools down and solidifies on the way down to the bottom of the chamber. Gas and plasma-atomization processes produce spherical shaped particles, and can atomize most metal materials. More information about atomization processes can be found eg. https://www.carpenteradditive.com/technical-library/

Below listed some metal material manufacturers/resellers, which have material specific properties listed on their websites.

| Link | Metal material |

| EOS | metal powders |

| SLM | metal powders |

| Markforged | plastic-metal filaments |

Other materials in general

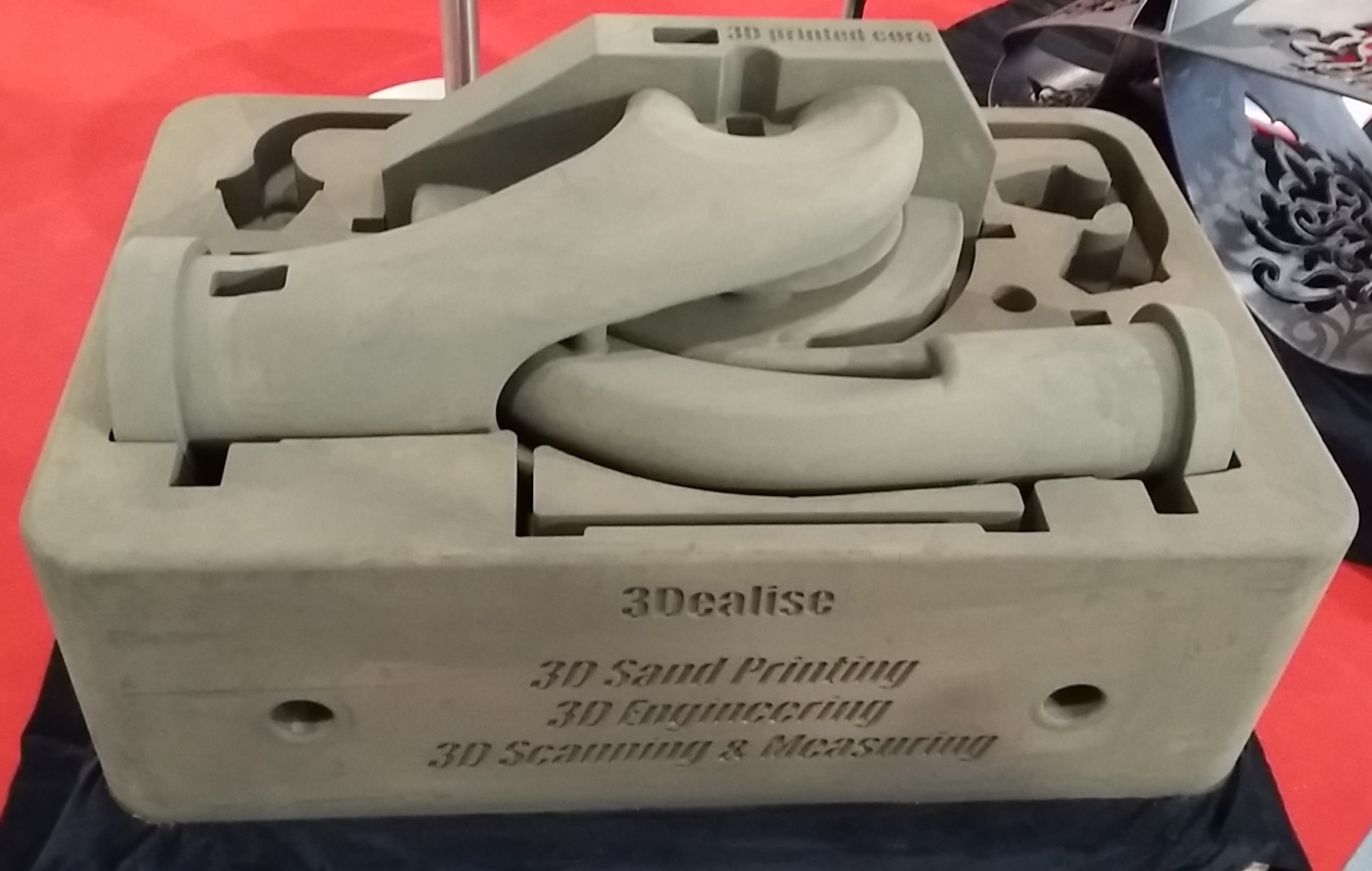

Other materials used in AM processes include: ceramics, sand, cloth, wax, food- and biomaterials. The most common from these is sand, which is used for example creating sandmolds for metal casting processes.

In Finland Hetitec Oy is a company printing models & molds from sand using Voxeljet 3D-printers.

Examples of AM-parts manufactured from sand:

Common for all materials

The material properties in AM are mainly similar to the materials used in traditional material reductive processes. Although there are some differences, ie. AM-part properties are affected among other things by printing orientation and the layered manufacturing, also in some cases material compositions and properties are altered on purpose, to optimize the material for the used AM-process.